Vatva, Ahmedabad, Gujarat

- GST NO. : 24AACCI2791M1ZB

1 Lac / piece

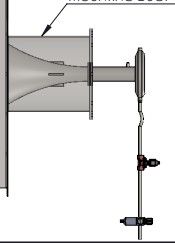

| Type | Condensate Recovery Pump |

| Application | To Move condensate Water to feed water tank |

| Color | Blue |

| Fuel | No Need |

| Click to view more | |

Product Details

Power

Pneumatic

Country of Origin

India

Make

Innovative Enerpro Pvt Ltd

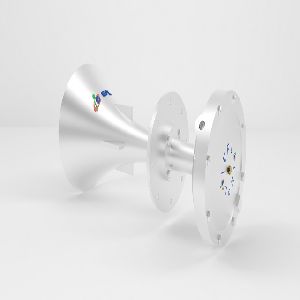

MECHANICAL CONDENASATE PUMPThere are Condensate recovery unit or power pressure pump use for transfer steamcondensate from plant to boiler feed water tank with help of motive steam or air.Working of Principal Condensate recovery pump or Power pressure pump: There are two stage of pump working 1) Filling Mode: Condensate from process will be collected in pump receiver tank due togravity it will open Check valve and start filling pumping tank. By this time motive inletis closed and vent outlet is open so there is no back pressure. This will lead level low tohigh.2) Pumping Mode: As the level reaches set high level vent valve shut off and open the motive steam or air valve. This will allow motive steam or air in tank and push the water level in downward direction. By this time Delivery Check Valve will be open and inlet check valve shut off.When low level reached automatically repeat the cycle. I.e. shut off the motive valveand open the exhaust.In Comman mechanical pump there are mechanical assembly which are very complicated and lot of moving part. It cost is to high. Also SS float puncture with time due to constant expansion and contraction due to temperature variation.While In our system "APPLIED FOR PATENT" We avoid complication of the operation. We remove ss float which are puncher after some time. We use special material float which can operate for almost life time. So there are no wear and tear will be there so it's almost maintenance free. Our system will be working for almost it's life cycle.Features1. Pump Total Material are SS 304 Material so life is long life.2. Float material is Special Materials so it will not punctured.3. No moving part assured zero maintenance.4. Suitable for high temp. Application. No cavitations problem5. Can be operated on compressed Air.6. Various sizes for different capacities.(max. cap.12,000 kg/hr)

Looking for "Iepl Condensate Recovery Pump" ?

piece

Explore More Products